If you are looking for lifting heavy loads manually, do not hesitate to look for EOT cranes. It simplifies the task and reduces the workforce. EOT crane is the right choice for construction sites, mining sites, workshops, and warehouses. The working temperature of the crane is -20 to 40°C. It is advisable to avoid using these cranes in a corrosive environment. Crane companies in India are manufacturing and designing the cranes based on the modern developments of different industries. They have also started providing customized designs according to the client’s needs.

What is the concept of the EOT crane?

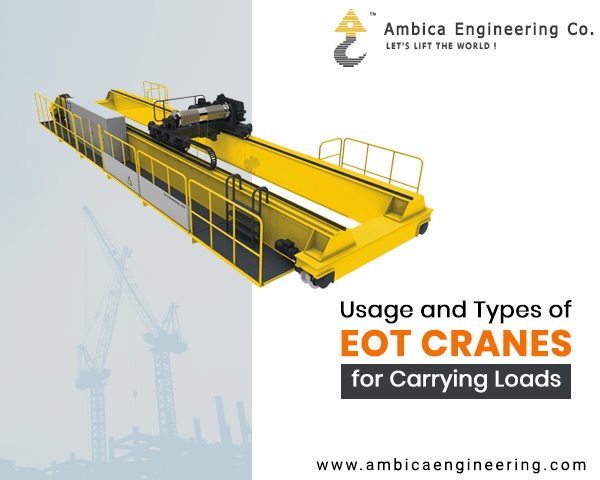

The Electric Overhead Traveling works as an overhead crane. Also known as bridge cranes, manufactured with the capacity to raise and lower bulky loads in both directions. The two main categories of EOT crane is Single Girder and Double Girder EOT Crane.

Single Girder Crane – These are lightweight structures equipped with once bridge. These are chosen for some lighter applications in your industry. Electrically managed hoist, end carriages, and the main bridge are the major components of these cranes.

Double Girder Crane – A double girder EOT crane model is affordable and with higher capacity than the single girder. Having two bridges, they are robust in structures. Heavy industries like construction sites can use these cranes. The crane company in India manufactures these cranes with quality assurance and because of its functionalities, a double girder EOT crane is a better choice. It comprises of hoisting mechanism, trolley running mechanism, and its frame. Hoisting is based on the brake and electric motor, drum, and reduction gear. Welding parts include the trolley frame which is useful for sustaining and installing the hoist.

Usage of EOT Crane

Capacity – Focus on the capacity of the crane and the material that you need to load or unload. It becomes if the capacity of the crane is lower than that of the material.

Inspection- Regular inspection is needed to check the condition of the crane before you perform any task for your industrial needs. It can be done daily, weekly, or even monthly based on its usage.

Loose parts – Disconnected parts or components can make the loading insecure and it can affect the loading. Tighten the hoisting ropes and the sling before using.

Double girder EOT crane functionality – It should function in a way that whenever needed, the crane can halt instantly. Before leaving the site, remember to turn down the system rightly. Remove the load from the hook of the EOT crane.

Ambica Engineering is the renowned crane manufacturers in Gujarat. They not only supply EOT cranes but also Goliath cranes and Jib Cranes. Contact us for more information on all kinds of cranes and the best tips to choose the right EOT crane.