Crane has become the quintessential machinery in modern times in many sectors of the economy. Be it construction, shipping, automotive, manufacturing, a crane plays an important role that enhances both productivity and safety.

No two cranes are alike and with so many different types of crane it is difficult to understand which crane is best fit for the application at your business. The most sought-after cranes providing economical and ergonomic lifting are gantry crane and jib crane.

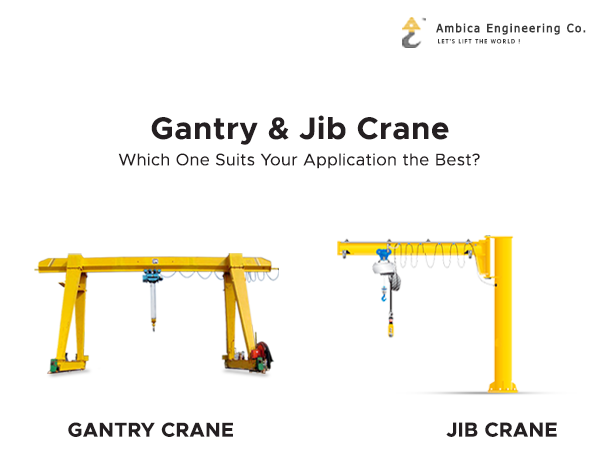

Gantry Crane

A gantry crane is the Electric Overhead Traveling (EOT) crane. It has a bridge which is supported by two A-frame steel legs. Some gantry crane run on the embedded rail on the floor and some are equipped with casters so that the crane can be moved conveniently to different places. They are extensively used in rail yards, shipping yards, various manufacturing industries, warehouses.

Jib Crane

A jib crane is not a typical EOT. It is mounted on a single leg (which is usually fixed to ground or wall) It is efficient in specific lift application, especially in production application where load positioning and spotting are critical. It provides great value and practical lifting solutions and many diverse applications that require circular coverage in tight spaces, supplementing a large overhead crane system.

To make a better suited decision for the application of correct crane in your business, it is advisable to consult experts of a trusted crane manufacturer of India.